Hey there! Are you looking to streamline your business operations and boost efficiency? Look no further than Production ERP Software. This powerful tool is designed to optimize production processes, improve inventory management, and enhance overall productivity. By incorporating ERP software into your business model, you can experience a wide range of benefits that will help your company thrive in today’s competitive market.

Overview of Production ERP Software

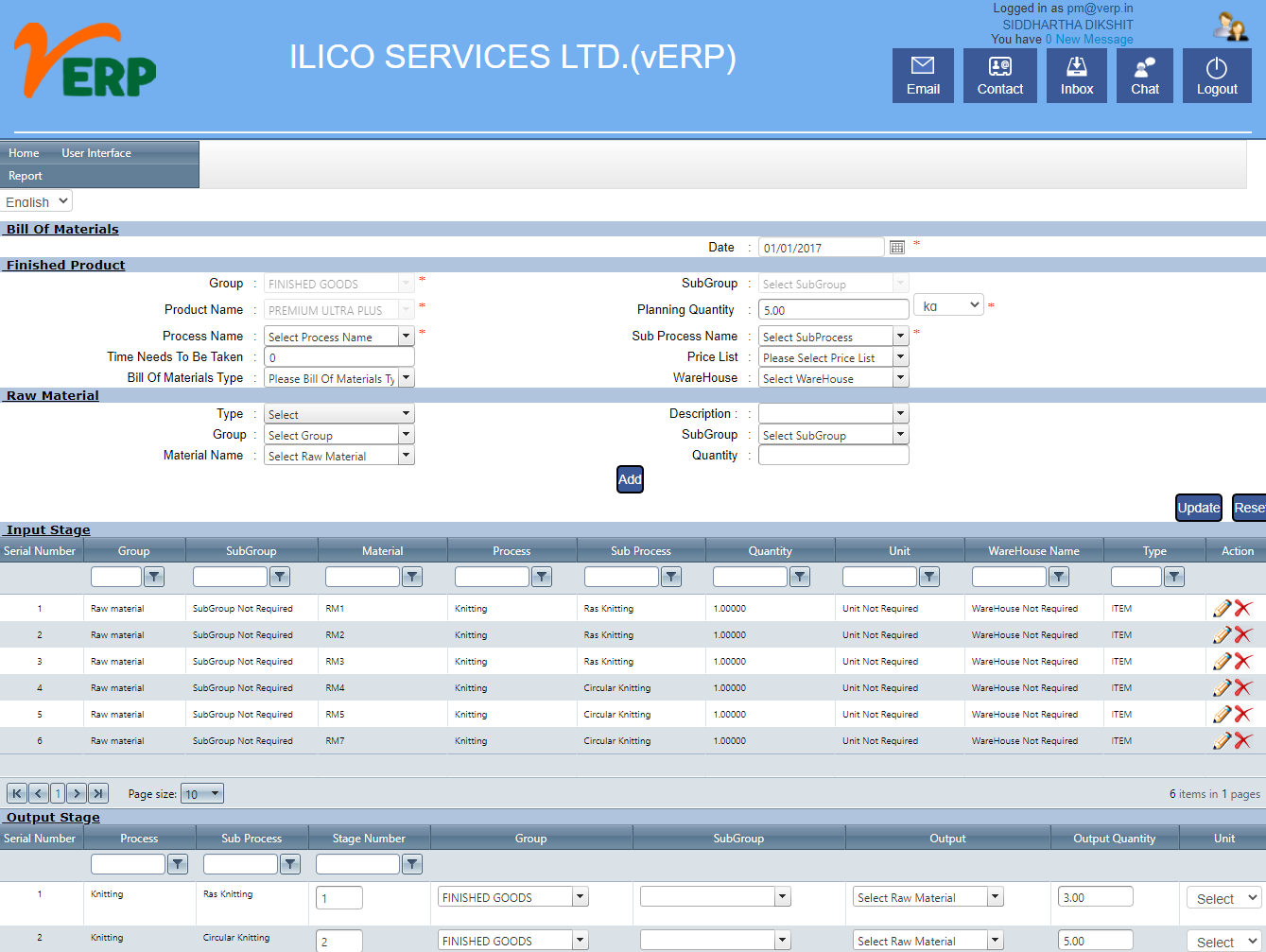

Production ERP software is a specialized system designed to help manufacturing companies manage and streamline their production processes. This type of software provides a centralized platform for tracking and controlling all aspects of production, from inventory and materials management to scheduling and quality control.

One of the key features of production ERP software is its ability to integrate with other systems, such as accounting and supply chain management, to provide a comprehensive view of the entire production operation. This integration allows for real-time data sharing and analysis, which can help companies make informed decisions and improve efficiency.

Production ERP software also offers tools for planning and scheduling production activities, optimizing resource utilization, tracking product costs, and monitoring quality control processes. By automating routine tasks and providing valuable insights into performance metrics, this software can help companies reduce costs, increase productivity, and enhance customer satisfaction.

Furthermore, production ERP software can help manufacturing companies comply with industry regulations and standards, such as ISO certifications and quality management systems. By providing documentation and audit trails for production processes, this software can help companies demonstrate compliance and improve their overall quality management practices.

In addition to its operational benefits, production ERP software can also provide strategic advantages for manufacturing companies. By analyzing historical data and market trends, this software can help companies identify opportunities for growth, optimize product offerings, and develop competitive strategies.

Overall, production ERP software is a valuable tool for manufacturing companies looking to improve their production processes, increase efficiency, and drive growth. With its comprehensive features and strategic insights, this software can help companies stay competitive in today’s fast-paced and dynamic business environment.

Key Features and Functions of Production ERP Systems

Production ERP systems are designed to streamline the manufacturing process and improve overall efficiency. These systems offer a wide range of features and functions to help businesses manage various aspects of production effectively.

One key feature of production ERP systems is inventory management. These systems allow businesses to track inventory levels in real-time, monitor stock levels, and automatically reorder supplies when inventory reaches a certain threshold. This helps to prevent stockouts and ensures that businesses always have the necessary materials on hand to meet production demands.

Another important feature of production ERP systems is production planning and scheduling. These systems help businesses create production schedules, assign resources, and track progress on various production tasks. By having a clear overview of the production process, businesses can optimize production schedules, identify bottlenecks, and improve overall efficiency.

Quality control is another critical function of production ERP systems. These systems allow businesses to track the quality of products at each stage of the production process, identify defects or issues, and take corrective actions to ensure that products meet quality standards. By maintaining high-quality standards, businesses can reduce waste, improve customer satisfaction, and enhance their reputation in the market.

Supply chain management is also a key feature of production ERP systems. These systems help businesses manage their entire supply chain, from sourcing raw materials to delivering finished products to customers. By providing visibility into the entire supply chain, businesses can identify opportunities for cost savings, optimize inventory levels, and streamline logistics processes.

Furthermore, production ERP systems often include integrated financial management tools. These tools help businesses track production costs, manage budgets, and generate financial reports to monitor the financial health of the production process. By having a comprehensive view of production costs, businesses can make informed decisions to improve profitability and reduce costs.

Overall, production ERP systems play a crucial role in helping businesses manage the complexities of the manufacturing process. By leveraging key features and functions such as inventory management, production planning, quality control, supply chain management, and financial management, businesses can optimize production processes, improve efficiency, and drive profitability.

Benefits of Implementing Production ERP Software

Production ERP software offers a wide range of benefits for businesses across various industries. From streamlining operations to increasing productivity, here are some key advantages of implementing production ERP software.

1. Efficiency and Cost Savings:

One of the primary benefits of using production ERP software is the ability to improve efficiency and save costs. By integrating all aspects of production processes into a single system, businesses can streamline operations and eliminate manual processes. This automation not only reduces the likelihood of errors but also saves time and resources. With real-time data tracking and reporting capabilities, companies can identify bottlenecks in production and make informed decisions to optimize processes and reduce waste.

2. Improved Decision Making:

Another significant advantage of production ERP software is the ability to make data-driven decisions. With all production data stored in one centralized system, managers can access real-time insights to monitor performance, track key metrics, and identify trends. This visibility allows businesses to identify areas for improvement, such as optimizing inventory levels or adjusting production schedules to meet demand. By having access to accurate and timely information, companies can make informed decisions that drive efficiency and profitability.

3. Enhanced Collaboration and Communication:

Production ERP software also enhances collaboration and communication among different departments within a business. With a centralized system, employees across various functions can easily access and share information, fostering a more collaborative and connected work environment. For example, sales teams can provide production teams with real-time updates on customer orders, enabling faster response times and improved customer satisfaction. The ability to communicate seamlessly across departments ensures everyone is on the same page, leading to better coordination and more efficient production processes.

4. Scalability and Flexibility:

Production ERP software is designed to grow with your business. As your company expands and evolves, the system can easily scale to accommodate increased production volumes, additional users, and new functionalities. This scalability ensures that your production processes remain efficient and effective as your business grows. Furthermore, production ERP software is highly customizable, allowing businesses to tailor the system to their specific needs and requirements. Whether you need to add new modules or integrate with third-party applications, production ERP software provides the flexibility to adapt to changing business needs.

In conclusion, implementing production ERP software can deliver numerous benefits for businesses looking to streamline operations, improve decision-making, enhance collaboration, and ensure scalability. By leveraging the power of a centralized system, companies can optimize production processes, reduce costs, and drive sustainable growth.

Considerations for Choosing the Right Production ERP Solution

When selecting a production ERP solution for your business, there are several key factors to consider to ensure you choose the right one that meets your company’s specific needs. Here are some important considerations to keep in mind:

1. Industry-specific Features: One of the most critical considerations when choosing a production ERP solution is whether it offers industry-specific features that align with your business requirements. Different industries have unique processes and workflows, so it’s essential to select a solution that caters to your specific industry vertical. For example, if you are in the manufacturing sector, look for an ERP system that offers advanced production scheduling, inventory management, and resource planning capabilities tailored to manufacturing operations.

2. Scalability: Another crucial factor to consider is the scalability of the ERP solution. As your business grows, your ERP system should be able to accommodate increased data volume, users, and processes without compromising performance. Make sure the solution you choose can scale with your business and adapt to changing requirements over time.

3. Integration Capabilities: A production ERP solution that seamlessly integrates with other critical business systems, such as CRM, accounting, and supply chain management, is essential for maximizing operational efficiency and data visibility. Look for a solution that offers robust integration capabilities to ensure smooth data flow between different business functions and eliminate silos.

4. Customization and Flexibility: When evaluating ERP solutions, consider the level of customization and flexibility they offer. Every business is unique, and your ERP system should be able to adapt to your specific business processes and requirements. Look for a solution that allows for easy customization, configuration, and flexibility to tailor the system to your company’s needs without extensive coding or development work. Additionally, consider the ease of integration with third-party applications and the availability of APIs for seamless connectivity.

5. User-Friendly Interface: User adoption is crucial for the success of any ERP implementation. Choose a production ERP solution with an intuitive and user-friendly interface that simplifies navigation and enhances user experience. A well-designed interface can improve productivity, reduce training time, and increase user satisfaction, leading to better overall system utilization and ROI.

6. Vendor Reputation and Support: Lastly, consider the reputation and support services offered by the ERP vendor. Choose a reputable vendor with a proven track record of successful ERP implementations and ongoing support services. Evaluate customer references, case studies, and reviews to gauge the vendor’s credibility and reliability. Additionally, ensure the vendor offers comprehensive support services, including training, maintenance, and upgrades, to help you maximize the value of your ERP investment.

By taking these considerations into account when selecting a production ERP solution, you can ensure you choose a system that aligns with your business goals, enhances operational efficiency, and drives long-term growth and success.

Case Studies: Successful Implementations of Production ERP Software

Implementing production ERP software can be a game-changer for businesses looking to streamline their operations, improve efficiency, and boost overall productivity. Successful case studies of companies that have implemented production ERP software showcase how this technology can revolutionize the way business is done.

One such success story is Company X, a manufacturing company that was struggling with inventory management and production scheduling. After implementing production ERP software, they were able to automate their inventory tracking, optimize production schedules, and reduce lead times. This resulted in a significant increase in productivity and a decrease in production costs for Company X.

Another example is Company Y, a food processing company that was facing challenges with batch tracking and quality control. By integrating production ERP software into their operations, they were able to track batches in real-time, monitor quality control metrics, and ensure compliance with industry regulations. This led to improved product quality, increased customer satisfaction, and a reduction in waste for Company Y.

Company Z, a clothing manufacturer, also saw tremendous benefits from implementing production ERP software. They were able to streamline their supply chain management, improve communication between departments, and track the entire production process from start to finish. This increased collaboration among team members, reduced errors in production, and ultimately led to faster turnaround times and increased profits for Company Z.

Furthermore, Company A, a technology company, utilized production ERP software to manage their complex engineering processes, track project timelines, and improve resource allocation. By centralizing their data and automating key tasks, they were able to increase project efficiency, reduce time-to-market for new products, and ultimately stay ahead of the competition in their industry.

Lastly, Company B, a pharmaceutical company, implemented production ERP software to enhance regulatory compliance, track ingredient traceability, and improve product safety measures. This enabled them to meet stringent industry standards, maintain accurate records of their processes, and ensure the highest levels of quality control in their products. As a result, Company B was able to strengthen their reputation as a reliable and trustworthy provider in the pharmaceutical industry.

Overall, these case studies highlight the diverse benefits of implementing production ERP software across different industries. From improving inventory management to enhancing quality control measures, production ERP software has the potential to revolutionize the way businesses operate and achieve sustainable growth in today’s competitive market.