Welcome to the world of process manufacturing ERP, where efficiency is key and productivity is paramount. In today’s rapidly evolving market, companies are constantly striving to streamline their production processes in order to stay competitive and meet customer demands. With the help of process manufacturing ERP systems, businesses can optimize their operations, reduce waste, and improve overall performance. By integrating all aspects of production – from planning and scheduling to inventory management and quality control – into a centralized system, organizations can achieve greater visibility and control over their entire manufacturing process. Let’s explore how process manufacturing ERP can revolutionize the way businesses operate and drive success in the modern marketplace.

Benefits of Process Manufacturing ERP

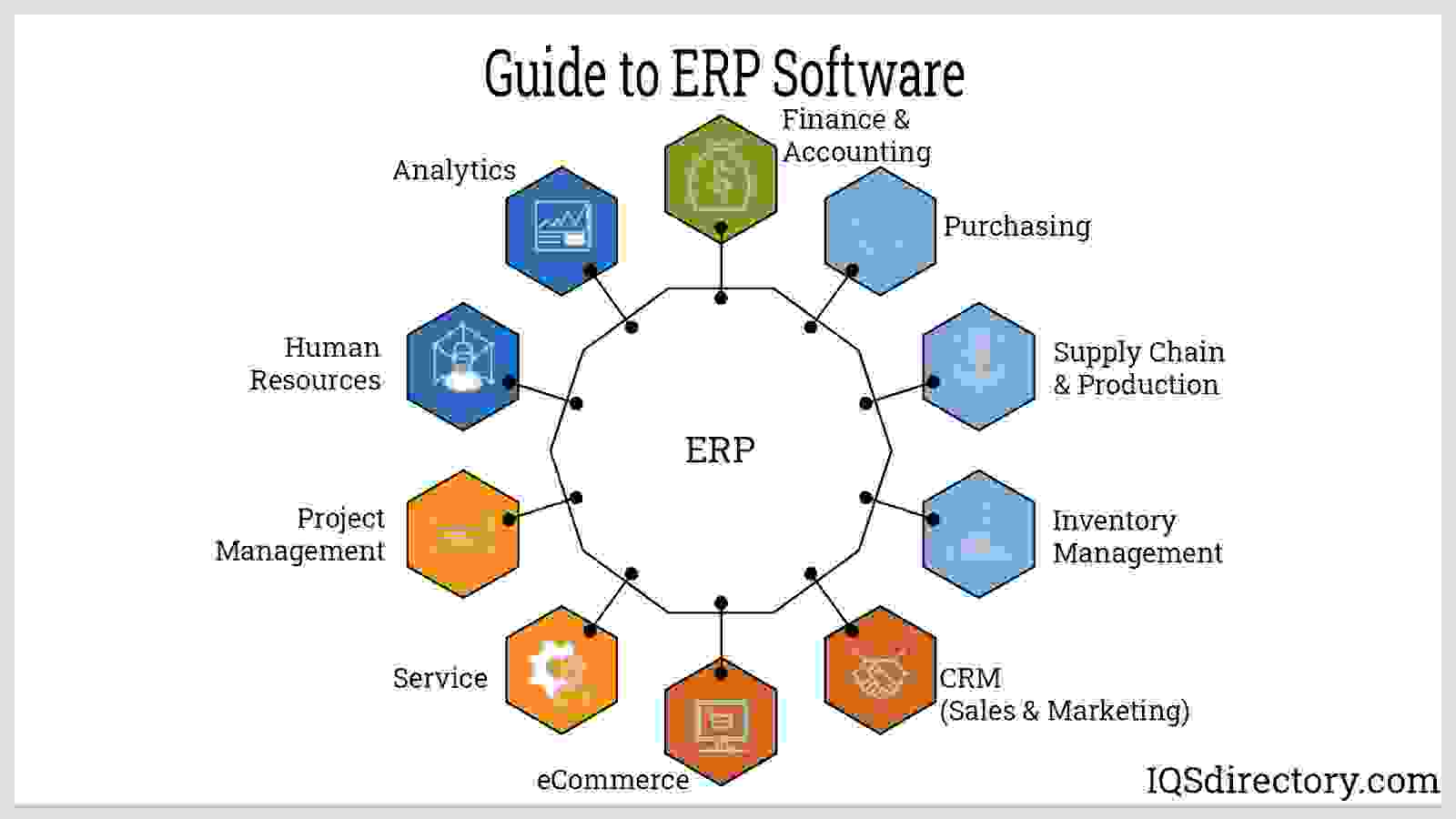

Process Manufacturing ERP (Enterprise Resource Planning) software is a valuable tool that can help manufacturers in the food and beverage, pharmaceutical, chemical, and other process industries streamline their business processes. Here are some key benefits of implementing a Process Manufacturing ERP system:

1. Improved Inventory Management: One of the main advantages of Process Manufacturing ERP is its ability to provide real-time visibility into inventory levels. With accurate data on hand, manufacturers can optimize their inventory levels, reduce carrying costs, and prevent stockouts or overstock situations. This can lead to improved efficiency and cost savings across the supply chain.

Furthermore, Process Manufacturing ERP systems often feature advanced inventory tracking capabilities, such as lot tracking and traceability. This is crucial for industries with strict regulatory requirements, as it allows manufacturers to quickly trace products back to their source in case of a recall or quality issue. By ensuring compliance with regulations and industry standards, manufacturers can avoid costly fines and protect their brand reputation.

In addition, Process Manufacturing ERP helps manufacturers plan their production schedules more effectively by providing insights into demand trends, production capacity, and resource availability. By aligning inventory levels with production requirements, manufacturers can minimize waste, improve resource utilization, and enhance overall operational efficiency.

Overall, improved inventory management through Process Manufacturing ERP leads to better decision-making, reduced operational costs, and increased customer satisfaction. Manufacturers can operate more efficiently, respond quickly to market changes, and ultimately drive business growth.

Key Features to Look for in a Process Manufacturing ERP System

When searching for a Process Manufacturing ERP system, there are key features that you should consider to ensure that the system meets the specific needs of your business. These features will help streamline your operations, maximize efficiency, and improve overall performance. Here are some essential features to look for:

1. Industry-specific functionality: One of the most important factors to consider when choosing a Process Manufacturing ERP system is industry-specific functionality. Make sure the system is designed to meet the unique needs of process manufacturing businesses, such as formula management, batch processing, quality control, and compliance requirements. Look for a system that offers specialized features tailored to the processes and operations of your industry.

2. Comprehensive reporting and analytics: A good Process Manufacturing ERP system should provide comprehensive reporting and analytics capabilities to help you make informed business decisions. Look for a system that offers customizable reports, dashboards, and real-time data analysis tools. These features will allow you to track key performance indicators, identify trends, and optimize your processes for maximum efficiency. With detailed insights into your operations, you can make strategic decisions that drive growth and profitability for your business.

3. Inventory management: Effective inventory management is essential for process manufacturing businesses to ensure smooth operations and avoid costly stockouts or overstock situations. Look for an ERP system that offers advanced inventory management features, such as real-time tracking, demand forecasting, and automated replenishment. The system should also support lot tracking and traceability to help you maintain product quality and comply with industry regulations.

4. Integration with other business systems: Seamless integration with other business systems is crucial for maximizing the efficiency and effectiveness of your Process Manufacturing ERP system. Look for a system that can easily integrate with your existing software applications, such as CRM, MES, and accounting systems. This will allow data to flow freely across all systems, eliminating silos and streamlining your operations.

5. Scalability and flexibility: As your business grows and evolves, your ERP system should be able to scale and adapt to meet your changing needs. Look for a system that is highly customizable and offers flexible deployment options, such as cloud-based or on-premise solutions. This will allow you to add new features, users, and functionalities as needed without disrupting your operations.

By considering these key features when selecting a Process Manufacturing ERP system, you can ensure that the system meets the specific requirements of your business and helps you achieve your operational and strategic goals. Investing in the right ERP system will enable you to streamline your processes, improve efficiency, and drive growth in your business.

Implementation Best Practices for Process Manufacturing ERP

Implementing a process manufacturing ERP system can be a complex and challenging task. However, by following some best practices, organizations can ensure a smooth and successful implementation process. Here are some key best practices to consider when implementing a process manufacturing ERP system:

1. Define clear objectives and goals: Before embarking on an ERP implementation project, it is essential to clearly define the objectives and goals of the system. This will help ensure that the ERP system is aligned with the organization’s overall business strategy and will guide the implementation process.

2. Assemble a skilled implementation team: A successful ERP implementation requires a team of skilled professionals with expertise in the system and the organization’s business processes. It is crucial to assemble a cross-functional team that includes representatives from various departments to ensure that all aspects of the implementation are covered.

3. Conduct thorough training and change management: One of the most critical factors in the success of an ERP implementation is adequate training and change management. It is essential to provide training to end-users on how to use the system effectively and ensure that they are comfortable with the new processes. Additionally, change management strategies should be implemented to help employees adapt to the new system and processes.

Training sessions should be tailored to the specific needs of each department and should include hands-on practice with the system. It is also helpful to provide training materials and resources that employees can refer back to as they become more familiar with the system. Additionally, regular communication about the implementation process and its progress can help keep employees engaged and informed.

Change management strategies should focus on addressing employees’ concerns and resistance to change. This may involve creating a culture of openness and transparency, providing regular updates on the implementation process, and involving employees in decision-making processes. It is essential to listen to employees’ feedback and address any issues that arise promptly.

By following these best practices for implementing a process manufacturing ERP system, organizations can increase the chances of a successful implementation and ensure that the system provides the intended benefits to the organization.

Case Studies: Successful Process Manufacturing ERP Implementations

When it comes to implementing Process Manufacturing ERP systems, success stories are worth noting. Let’s delve into some case studies of companies that have successfully implemented ERP solutions tailored to their process manufacturing needs.

One such example is XYZ Foods, a food processing company that was facing challenges with inventory management, quality control, and production planning. By implementing a Process Manufacturing ERP system, XYZ Foods was able to streamline their production processes, improve traceability of ingredients, and enhance overall operational efficiency. This resulted in reduced wastage, better resource utilization, and increased customer satisfaction.

Another success story comes from ABC Pharmaceuticals, a company in the pharmaceutical industry that implemented a Process Manufacturing ERP solution to address compliance requirements, batch tracking, and formula management. With the new ERP system in place, ABC Pharmaceuticals experienced improved visibility into their manufacturing processes, better control over production costs, and faster time-to-market for new products. The company also achieved regulatory compliance standards more easily, thanks to the automated documentation and reporting features of the ERP system.

Additionally, DEF Chemicals is a chemical manufacturing company that successfully implemented a Process Manufacturing ERP system to optimize their supply chain, enhance formula management, and improve batch tracking. With the new ERP solution, DEF Chemicals saw significant improvements in inventory management, production scheduling, and quality control. The company was able to reduce lead times, minimize stockouts, and respond more quickly to customer demands, ultimately leading to increased profitability and market competitiveness.

Lastly, GHI Cosmetics is a beauty product manufacturer that transformed their operations by implementing a Process Manufacturing ERP system. The company was facing challenges with inventory accuracy, formula consistency, and production efficiency. After deploying the ERP solution, GHI Cosmetics achieved real-time visibility into their inventory levels, ensured consistency in product formulations, and optimized their production processes for maximum output. As a result, the company was able to meet customer demands more effectively, launch new products faster, and improve overall profitability.

These case studies demonstrate the tangible benefits of implementing Process Manufacturing ERP systems for companies in various industries. By choosing the right ERP solution and tailoring it to their specific manufacturing needs, organizations can streamline their operations, improve compliance adherence, and drive sustainable growth in the competitive market landscape.

Future Trends in Process Manufacturing ERP Technology

Process manufacturing ERP technology is constantly evolving to meet the changing needs of manufacturers in various industries. Here are some future trends to look out for in the world of process manufacturing ERP:

1. Cloud-Based Solutions: As technology advances, more and more process manufacturing ERP systems are moving towards cloud-based solutions. This allows for easier access to data, scalability, and reduced maintenance costs. With cloud-based ERP, manufacturers can access real-time data and analytics from anywhere, improving decision-making processes and overall efficiency.

2. Integration with IoT: The Internet of Things (IoT) has transformed the manufacturing industry, and process manufacturing ERP systems are no exception. Integrating IoT devices with ERP systems allows manufacturers to gather real-time data on machines, processes, and products. This data can be used to optimize production processes, predict maintenance issues, and improve overall product quality.

3. Artificial Intelligence and Machine Learning: AI and machine learning technologies are becoming more prevalent in process manufacturing ERP systems. These technologies can analyze large amounts of data to identify patterns, optimize production schedules, and predict equipment failures. AI and machine learning can help manufacturers make more informed decisions, reduce waste, and improve overall productivity.

4. Increased Automation: Automation is a key trend in process manufacturing ERP technology. With the rise of robotic process automation (RPA) and other automated technologies, manufacturers can streamline processes, reduce manual errors, and increase efficiency. Automation can also help manufacturers adapt to changing market demands and improve customer satisfaction.

5. Focus on Sustainability: In the future, process manufacturing ERP systems will likely place a greater emphasis on sustainability and environmental impact. Manufacturers are under increasing pressure to reduce their carbon footprint and minimize waste. ERP systems can help manufacturers track and optimize resource usage, reduce energy consumption, and comply with environmental regulations. By integrating sustainability practices into ERP systems, manufacturers can improve their reputation, attract eco-conscious customers, and contribute to a healthier planet.

As technology continues to advance, process manufacturing ERP systems will evolve to meet the changing needs of manufacturers. By embracing cloud-based solutions, integrating IoT devices, leveraging AI and machine learning technologies, increasing automation, and focusing on sustainability, manufacturers can stay ahead of the curve and remain competitive in a rapidly changing industry.