Welcome to the essential guide to ERP manufacturing software! If you’re looking to streamline your manufacturing processes, increase efficiency, and improve overall productivity, then you’ve come to the right place. In this article, we will dive into the world of ERP manufacturing software, exploring its benefits, features, and how it can revolutionize the way you do business. Whether you’re a small business looking to scale or a large enterprise seeking to optimize operations, ERP software can be a game-changer for your business. So sit back, relax, and let’s explore the world of ERP manufacturing software together.

Key Features of ERP Manufacturing Software

ERP Manufacturing Software offers a wide range of key features that can streamline and optimize the manufacturing process for businesses of all sizes. One of the main features of ERP Manufacturing Software is inventory management. This feature allows businesses to track their inventory levels in real-time, ensuring that they always have the right amount of raw materials on hand to meet production demands. The software can also help businesses automate the reordering process, minimizing stockouts and excess inventory.

Another important feature of ERP Manufacturing Software is production planning and scheduling. This feature helps businesses optimize their production processes by creating schedules that maximize the efficiency of their resources. By analyzing historical production data and current demand forecasts, the software can recommend the best production schedules to meet customer orders while minimizing production costs.

Quality management is another key feature of ERP Manufacturing Software. This feature allows businesses to track and manage the quality of their products throughout the production process. By setting quality control checkpoints at various stages of production, businesses can ensure that only high-quality products are delivered to customers. The software can also generate reports on quality metrics, helping businesses identify areas for improvement.

Supply chain management is also a critical feature of ERP Manufacturing Software. This feature allows businesses to manage their entire supply chain from a single platform, ensuring that they have visibility into their suppliers, vendors, and logistics partners. By automating the procurement process and tracking supplier performance, businesses can reduce supply chain costs and minimize the risk of supply chain disruptions.

One of the key benefits of ERP Manufacturing Software is its ability to integrate with other systems, such as accounting and customer relationship management (CRM) software. This integration allows businesses to streamline their operations and access real-time data from multiple sources, enabling informed decision-making. By centralizing data and processes, ERP Manufacturing Software can help businesses improve collaboration and communication across departments.

Benefits of Implementing ERP in Manufacturing

Implementing ERP (Enterprise Resource Planning) software in manufacturing companies can provide numerous benefits that contribute to overall operational efficiency and business success. Here are some of the key advantages of utilizing ERP systems in the manufacturing industry:

1. Streamlined Processes: One of the main benefits of implementing ERP in manufacturing is the ability to streamline various business processes. From order management to inventory control, production planning to financial management, ERP software integrates all these functions into a single platform, eliminating the need for manual data entry and reducing the risk of errors. This streamlining of processes helps to increase productivity, reduce operational costs, and enhance overall operational efficiency.

2. Enhanced Inventory Management: ERP systems provide manufacturing companies with real-time visibility into their inventory levels, allowing them to better track stock levels, monitor product movements, and manage materials effectively. With ERP software, manufacturers can automate inventory control processes, set up reorder points, and optimize stock levels based on demand forecasts. This results in reduced stockouts, minimized excess inventory, and improved inventory turnover rates. Additionally, ERP systems help in tracking the movement of raw materials and finished goods, ensuring accurate and timely deliveries to customers.

3. Improved Production Planning: ERP software enables manufacturers to optimize their production planning and scheduling processes by providing comprehensive insights into production capacities, resource availability, and lead times. By integrating production planning with other functions such as sales, procurement, and inventory management, ERP systems help manufacturers to better align production schedules with customer demand, reduce lead times, and improve on-time delivery performance. This leads to higher production efficiency, increased customer satisfaction, and enhanced competitiveness in the market.

4. Better Quality Control: With ERP systems, manufacturing companies can implement robust quality control measures throughout the production process, starting from raw material inspection to final product testing. By capturing and analyzing quality data in real-time, manufacturers can identify and address quality issues quickly, trace product defects back to their source, and implement corrective actions to prevent recurrence. This proactive approach to quality control helps manufacturers to deliver high-quality products, reduce rework and scrap costs, and maintain compliance with industry standards and regulations.

5. Enhanced Reporting and Analytics: Another significant benefit of implementing ERP in manufacturing is the ability to generate comprehensive reports and analytics that provide valuable insights into business performance, production efficiency, and cost management. ERP systems offer customizable reporting tools that allow manufacturers to track key performance indicators, analyze trends, and make informed decisions based on real-time data. By having access to accurate and up-to-date information, manufacturing companies can identify opportunities for improvement, optimize resource utilization, and drive continuous business growth.

In conclusion, the implementation of ERP software in manufacturing can revolutionize the way companies operate by streamlining processes, improving inventory management, enhancing production planning, ensuring quality control, and enabling better decision-making through reporting and analytics. By leveraging the benefits of ERP systems, manufacturing companies can stay competitive, adapt to changing market demands, and achieve sustainable growth in today’s dynamic business environment.

Successful Case Studies of ERP in Manufacturing

Implementing ERP software in the manufacturing industry has been proven to streamline processes, improve efficiency, and increase profitability. Here are three successful case studies showcasing the benefits of ERP in manufacturing:

Case Study 1: Toyota

Toyota implemented ERP software to help manage their complex supply chain and production processes. By utilizing ERP, Toyota was able to improve inventory management, reduce production lead times, and enhance communication between departments. This resulted in significant cost savings and improved overall efficiency for the company.

Case Study 2: Siemens

Siemens, a global leader in manufacturing technology, implemented ERP software to centralize their business operations and improve decision-making processes. By using ERP, Siemens was able to consolidate data from different departments, optimize production schedules, and enhance quality control measures. This led to increased productivity, reduced errors, and improved customer satisfaction.

Case Study 3: Apple

Apple, known for its innovative products and supply chain management, implemented ERP software to streamline their manufacturing processes and improve visibility into their supply chain. By leveraging ERP, Apple was able to track inventory levels in real-time, forecast demand accurately, and coordinate production schedules more effectively. This resulted in reduced lead times, lower costs, and increased profitability for the company.

Overall, these case studies demonstrate the transformative impact of ERP software in the manufacturing industry. Companies that have implemented ERP have seen improvements in operational efficiency, cost savings, and overall business performance. By investing in ERP technology, manufacturing companies can stay competitive, adapt to changing market demands, and achieve sustainable growth in the long run.

How to Choose the Right ERP Software for Manufacturing

Choosing the right ERP software for your manufacturing business is crucial for streamlining operations, improving efficiency, and staying competitive in the market. With the multitude of options available today, it can be overwhelming to decide which ERP system is best suited for your specific needs. Here are some key factors to consider when selecting ERP software for manufacturing:

1. Define Your Business Needs: Before you start browsing through ERP software options, take the time to clearly define your business needs and goals. Consider what specific challenges you want the ERP software to address, whether it’s inventory management, production scheduling, quality control, or compliance with industry regulations. By understanding your unique requirements, you can narrow down your options and focus on solutions that align with your business objectives.

2. Scalability and Flexibility: As your manufacturing business grows, you need an ERP system that can scale with you. Look for software that offers flexibility to accommodate changing business requirements, such as adding new modules, integrating with third-party applications, or expanding to multiple locations. Scalability is essential for long-term success and ensures that your ERP software can support your evolving business needs.

3. Industry-Specific Functionality: Not all ERP software is created equal, especially when it comes to industry-specific functionality. Choose a system that is tailored to the manufacturing industry, with features and modules designed to address the unique challenges and requirements of your sector. Whether you’re in automotive, electronics, food and beverage, or any other manufacturing niche, make sure the ERP software has the necessary tools to optimize your operations and improve efficiency.

4. User-Friendly Interface and Training: One of the most critical factors in a successful ERP implementation is user adoption. To ensure smooth integration and maximum ROI, choose software with a user-friendly interface that is intuitive and easy to navigate. Look for ERP systems that offer comprehensive training and support to help your employees learn how to use the software effectively. A well-designed interface and proper training can minimize resistance to change and increase overall productivity in your manufacturing processes.

5. Integration Capabilities: In today’s interconnected business landscape, integration capabilities are essential for seamless data flow and communication between different systems. Choose an ERP software that can integrate with your existing applications, such as CRM, accounting, or inventory management systems. Seamless integration eliminates manual data entry, reduces errors, and improves collaboration across departments, leading to a more efficient and connected manufacturing operation.

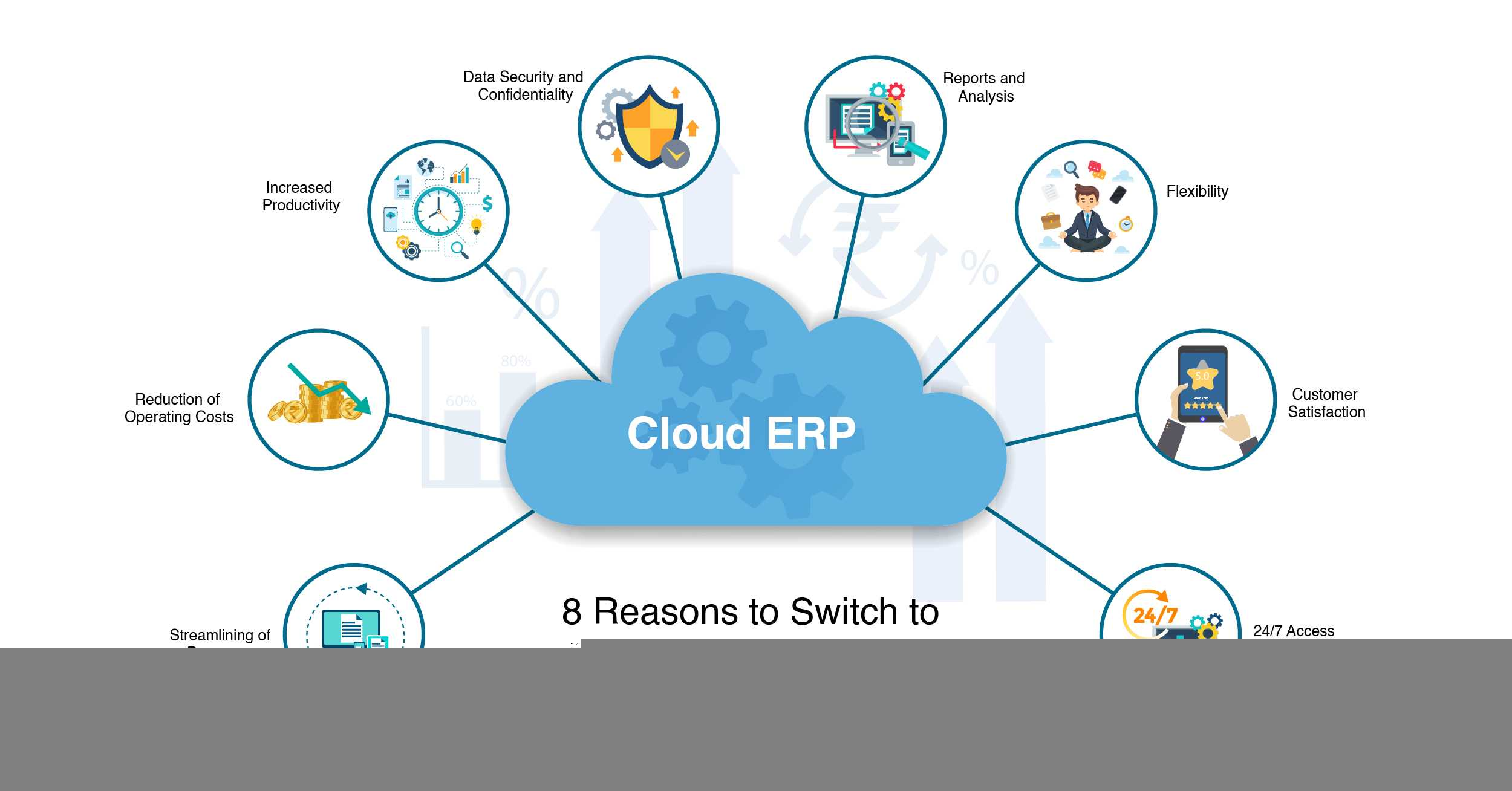

6. Cloud vs. On-Premises: When choosing ERP software for manufacturing, consider whether you want a cloud-based solution or an on-premises deployment. Cloud ERP offers benefits such as lower upfront costs, easy scalability, and anytime, anywhere access. On the other hand, on-premises ERP provides greater control over data security and customization. Evaluate the pros and cons of each deployment option based on your budget, IT resources, and business requirements to make an informed decision.

By considering these key factors and conducting thorough research, you can choose the right ERP software for manufacturing that aligns with your business goals and drives growth and success in the long run.

Future Trends in ERP Manufacturing Software

As technology continues to evolve, the future of ERP manufacturing software is poised for some exciting advancements. Here are five trends to keep an eye on:

1. Cloud-based Solutions: One of the most significant trends in ERP manufacturing software is the shift towards cloud-based solutions. Cloud ERP systems offer increased flexibility, accessibility, and scalability compared to on-premise solutions. This trend is expected to continue as more manufacturers realize the benefits of cloud-based software.

2. Integration with IoT: The Internet of Things (IoT) is revolutionizing the manufacturing industry by enabling machines to communicate with each other and with ERP systems in real-time. Future ERP software will be increasingly integrated with IoT devices, allowing manufacturers to collect and analyze data more effectively for improved decision-making.

3. Artificial Intelligence and Machine Learning: AI and machine learning are already making waves in the ERP industry, and their impact will only continue to grow. These technologies can automate repetitive tasks, predict maintenance needs, optimize production schedules, and provide valuable insights for process improvement. In the future, AI and machine learning will be even more integral to ERP manufacturing software.

4. Mobile Accessibility: With the rise of remote work and the importance of real-time data access, mobile accessibility is becoming a must-have feature for ERP software. Manufacturers need to have the ability to access their ERP systems on the go, whether they are on the shop floor or working from home. Future ERP solutions will prioritize mobile accessibility to meet the needs of modern manufacturers.

5. Enhanced Data Security and Privacy: As manufacturers collect and store increasing amounts of sensitive data in their ERP systems, cybersecurity is a growing concern. Future ERP software will place a greater emphasis on data security and privacy measures to protect against cyber threats. This may include advanced encryption protocols, multi-factor authentication, and regular security audits to ensure that manufacturers’ data is safe and secure.

Overall, the future of ERP manufacturing software is bright, with exciting advancements in cloud-based solutions, IoT integration, AI and machine learning, mobile accessibility, and data security. Manufacturers who stay ahead of these trends will be better equipped to streamline their operations, improve their decision-making processes, and stay competitive in today’s rapidly evolving market.